When I first saw the strawberry wheels from Dyson, I dismissed it as yet another attempt from engineers to “solve” vertical farming with rotating infrastructure to reduce the reliance on artificial lighting and electricity. Recently the media, podcasters, and youtubers seem to have discovered this system (at least according to my internet feed) and are claiming that vertical farming has been finally solved. So, I decided to dig into it a little bit more. I wanted to see if this engineering tech company had come up with anything that would truly solve vertical farming that hadn’t already been done in slightly different form factor before.

Reinventing the wheel

Tucked away in the English country side is a glasshouse with two massive contraptions, 500 kg (~1,100) geared wheels support 480 linear meters (1575 ft) of strawberry crops. These slowly rotate to ensure that all the plants receive natural sunlight from above and have supplemental lighting below to make up the difference. Not going to lie, it looks pretty cool, but it took two years for them to build, from scratch, designing most of the components themselves instead of sourcing the parts elsewhere.

I’m sure that from a functional standpoint the system works and does so decently. However, everyone, myself included, is quick to point out the intensive capital costs are prohibitive to successful controlled environment agriculture. So that begs the question, “Is the cost of rotating the crops less than the cost of electricity saved?”. Without concrete numbers of production quantities and the associated costs that would be tricky to figure out. Especially since this is a mere test bed in something much larger and more promising.

The Real Greenhouse

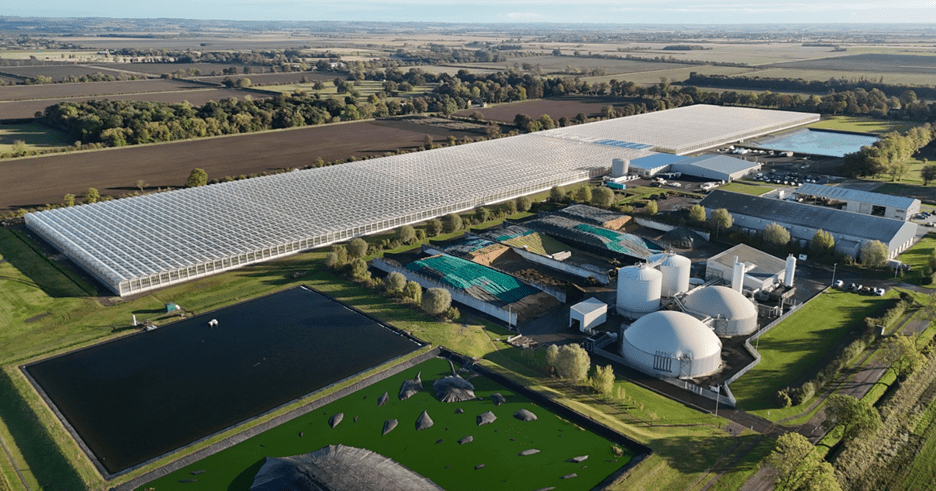

Turns out Dyson owns at least 36,000 acres of farmland in the English country side, 26 acre of which is a glasshouse with over a million strawberry plants. For comparison the wheeled system is simply 0.04% the size of the real strawberry production (480 vs 1,106,560 linear meters). It looks remarkably similar to other strawberry greenhouses, with rows of plants supported above the ground however this one is managed heavily by automated robots instead people. This greenhouse is where the real production happens, however it isn’t the fact that UV light is wheeled around to destroy molds, or aphid eating bugs are delivered directly to the plants that make this glasshouse worth talking about. The connection it has to the entire Dyson farming ecosystem and the surrounding area is what is truly special.

Circularity, the undersold star of the show

The Dyson glasshouse is an example of circular agriculture in practice, with anaerobic digestion as the centerpiece. Anaerobic digestion is a fermentation process where organic materials are broken down by microbes in the absence of oxygen producing nutrient rich digestate and biogas which can be burned for energy. However, 26 acres of glasshouse strawberry waste products wouldn’t be a great feedstock for the process, decreasing biogas yield. Fortunately, one of the prime feedstocks for digestors, cattle manure, is produced nearby on some of the thousands of acres operated by Dyson farming.

That along with other leftover biomass from their farms allow the digestors to produce a lot of biogas. Which is then used to drive turbines and produce 41,6100 MWh of electricity alongside using the waste heat for the glasshouses. That amount is more than the farm requires with the rest delivering energy to thousands of nearby homes. The digestate then returns to the fields as an organic fertilizer creating a circular loop of biomass and resources. This is the future of vertical farming, a reintegration into an agricultural ecosystem with an emphasis on cycling resources between different biological systems.

Conclusion

Dyson Farming is not the first or only farm doing this style of agriculture, even my local dairy grows crops fertilized with digestor effluent that is used to then feed cows which create more digestor feedstock and biogas for the grid. However, Alliance Dairies isn’t getting praised for overengineering something which has been done before. Dyson, and the media, had a chance to inspire and educate about the benefits of circularizing agricultural resources flows, but instead focused in on an expensive and eye-catching new piece of technology with limited potential and scalability.

If a new method of stacking plants vertically was going to “solve” vertical farming one of the many startups would have figured that out in the last 20ish years. However, it always comes down to resource flows and costs being the true deciding factor of vertical farming success. These can be improved with more circular management of materials within controlled environment agriculture and integration into a larger diverse agroecosystem to maximize production and utilization efficiencies across the different types of farming.

©Donald Coon 2025 available at https://doi.org/10.5281/zenodo.17502720

This work is licensed under CC BY 4.0